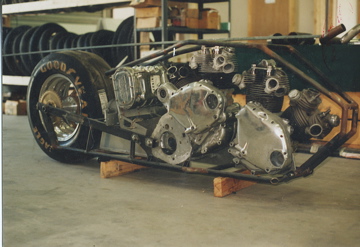

I thought it might be a good idea to put the power units in a drag bike chassis, where testing could be done at the drags on a weekly basis, testing all of the components for that ever so elusive reliability that would be required to do the job.

So the engines were mocked up and installed with blower in a drag frame I built.

After a couple of months I realized that this would take the better part of a year and a lot of money, so I shelved the project.

I wanted to get on with the quest, however, and I felt a quickie could be built, testing only the problems of two engines coupling together.

Having built several racing Vincents, I felt I could manage the engines without a problem.

The blower and the fuel injection was again no problem.

The only gray area in my bank of knowledge was in coupling them together.

From my racing at the local drag strips I had observed that virtually all of the double engine machines, particularly the Harleys, had a problem in the coupling.

More often than not they were spinning the chains off.

I built the quickie using a couple of Mustang motor scooter engines.

My principle concern was to better understand harmonic vibrations that occur, and find out what effect they have on coupling components, i.e. chain, sprockets, shaft and chain adjusters, all important and subject to failure.

It's best time at the drags was 103 mph.

I can't remember the ET.

Not bad, huh, for a motor scooter.

|